Long Beach

The Challenge

Without protective coating, columns cracked and spalled.

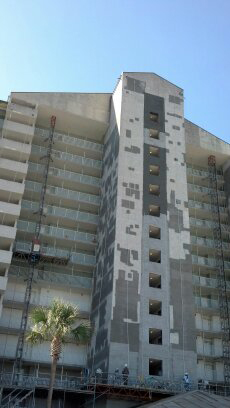

The Long Beach Resort Community had property-wide problem: extensive weakening of structural concrete and water infiltration because waterproofing had not been installed during original construction. Resort management recognized that repairs were essential and called in Pendleton+Bowman (P+B) to perform a comprehensive audit of Tower II, the property’s oldest structure. The firm’s goal was to assess and ameliorate damage so building integrity was maintained while causing minimal disruption to residents.

P+B uncovered multiple defects needing immediate attention and repair, including delaminating stucco, major concrete spalling and leaky windows. Columns had no protective coating, so cracks that formed over time allowed salt-laden chloride to react with reinforcing steel, causing the steel to rust and expand and subsequently crack and spall the concrete.

Control joints allowed saltwater to seep into the stucco.

Control joints in walls allowed saltwater to leak in, turning stucco into a giant sponge that held moisture and rusted stub nails. The stucco’s heavy texture presented technical waterproofing challenges as well. No properly installed sealant joints existed around windows, allowing water to seep into the wall cavity.

Uncoated balcony slabs

Removing disbanded tile revealed that balcony slabs were also uncoated. Additionally, guard rail stanchions were installed in core drilled holes placed extremely close to the slab edge which, coupled with saltwater exposure, caused them to crumble.

Taking Action

After laboratory testing to assure concrete columns were sound, the P+B team made repairs and applied a waterproof coating. All balcony tile was removed, concrete was repaired and a waterproof coating was applied to those areas as well.

The tower’s paper-backed stucco was severely compromised, but P+B was able to salvage it by drilling through to the metal lath beneath and securing the stucco with 3/4" pins.

The team then worked to identify the best means to seal the heavily textured stucco surface. Multiple methods were mocked up and analyzed for waterproofing effectiveness, application ease, appearance and cost. It was determined that concrete block filler should be used for micro-cracks, while larger cracks were to be ground open and filled with sealant, followed by a waterproof coating for the entire structure.

P+B custom-designed a joint to seal the face of the window frame within the structural concrete.

Windows were placed in contact with structural concrete, so a proper joint could not be installed. Instead, the team designed a custom joint that sealed the face of the window frame, and flashing was installed with a vertical leg to direct water away from the building.

Over 100 edge spalls caused by water penetration around guard rail stanchions were cited, and 15 emergency repairs were made to prevent rail failure as a temporary measure. Then, the team oversaw installation of new rails with welded connections that prevent galvanic corrosion and deter water infiltration.

In spite of the complexity, scope and many unknowns involved, the entire project was completed on budget and within the promised six-month time frame. The project was so successful that P+B have been engaged to complete repair and restoration on the remaining three towers as part of a 10-year strategic plan.